Long Bridge South Design-Build

Arlington, VA and Washington, DC

| Location: | Arlington, VA and Washington, DC |

| Owner: | Virginia Passenger Rail Authority (VPRA) |

| Construction Company: | Long Bridge Rail Partners, a joint venture of Trumbull Corp.; Fay, S&B USA Construction; and Wagman Heavy Civil, Inc. |

| Designer: | STV & Dewberry |

| Project Status: | Construction is expected to begin in Fall 2026 with estimated substantial completion in 2030 |

Fay, S&B USA Construction (Fay) is in the design stage of a design-build project for the Virginia Passenger Rail Authority (VPRA) to deliver the Long Bridge South Package. The project comprises a new two-track railroad bridge and a bicycle/pedestrian bridge that will be constructed from Arlington, VA over the Potomac River to Washington, DC. The project will increase passenger rail capacity to meet future rail needs through this busy rail corridor.

Innovative Concepts Will Increase Rail Capacity in Nation’s Capital Sooner and at Lower Cost

Project Highlights

- Two-track railroad bridge adjacent to the current Long Bridge rail crossing

- Bicycle/pedestrian bridge for improved public access to riverside trails and amenities

- Early works including demolition, sitework, and utility relocations

- Retaining walls and associated embankments

- Fender system within the Potomac River Navigational Channel

This animation reflects preliminary project plan.

The current Long Bridge carries rail traffic via two tracks over the Potomac River between Arlington, VA and Washington, DC. Owned and operated by CSX Transportation (CSXT), the Long Bridge operates at 98% capacity during peak hours with nearly 80 CSXT, Amtrak, and Virginia Railway Express (VRE) trains crossing it daily and carrying up to 1.3 million Amtrak passengers and 4.5 million VRE commuters annually. This railroad corridor is a vital link connecting local, regional, and national transportation networks, but current service along the corridor does not provide sufficient capacity and redundancy to meet projected demand for railroad services.

To address this bottleneck, VPRA is leading the Long Bridge Project to make rail improvements that will separate passenger and freight traffic while maintaining interoperability of passenger and freight rail across four tracks. The project comprises two construction contracts: the North Package and the South Package.

The South Package will construct a new, two-track rail bridge and an adjacent bicycle/pedestrian bridge over the Potomac River. These new structures will be adjacent to CSXT’s existing Long Bridge that will be retained. The South Package work will connect with the North Package rail infrastructure improvements already in progress in Washington, DC. Long Bridge Rail Partners (LBRP), a joint venture of Trumbull Corp.; Fay; and Wagman Heavy Civil, were selected to deliver the South Package.

At completion, the two new tracks will enable separation of passenger and freight rail traffic across the four tracks of the current and new rail bridges to enhance transportation connectivity and efficiency. Additionally, the bicycle/pedestrian crossing will connect regional residents and visitors from the Jefferson Memorial and East Potomac Park to the Mount Vernon Trail and other Northern Virginia amenities.

Challenges

This project involves a tight urban setting with limited staging, laydown, and access opportunities; active rail coordination and tie-ins to adjacent projects; and environmental restrictions inherent to constructing a bridge over the Potomac River. The project site is in close proximity to the current Long Bridge, Interstate 395, and Reagan National Airport. During the procurement process, VPRA also wanted to better understand the methods and phases of constructing the new rail and pedestrian bridges in the tight space adjacent to the current Long Bridge.

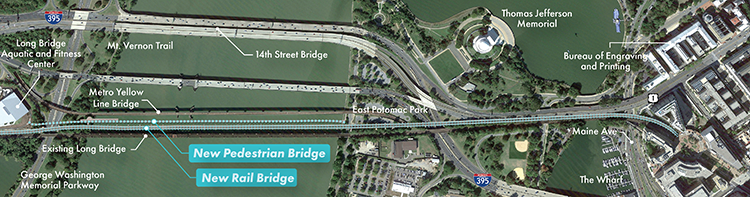

Map showing the locations of the existing Long Bridge and the new rail and pedestrian/bicycle bridges. (Credit: Virginia Passenger Rail Authority)

Solutions

During the procurement process, Fay’s engineers used 4D modeling capabilities—adding the element of time to 3D models—to create an animated visualization of what the joint venture team will build, how they will build it, and their proposed risk mitigation throughout construction. Fay and its JV partners used this 4D modeling capability to show VPRA’s team a detailed animation of phases, methods, and timing to construct both planned bridges. This use of technology facilitates the design-build delivery method.Additionally, the project team proposed several creative construction methods to limit interruptions to project stakeholders and the surrounding communities while delivering the highest-quality project with predictable durations and cost benefits. These proposed methods, which are pending the client’s approval, include:

- Floating vs. Trestle: The JV team proposed erecting the new railroad bridge using low-profile floating equipment that reduces impacts to the river, does not interfere with the adjacent rail bridge, and eliminates any need for cranes and other equipment to enter the restricted airspace. This approach eliminates a costly, time-consuming temporary trestle bridge requiring dozens of pipe piles and steel for the superstructure, erected by a traditional crane causing disruption of service to the adjacent rail bridges and FAA restricted air space.

- Pre-cast Footer Tubs: Traditional footing construction for the bridge piers would require cofferdams around all 22 pier foundations, which would take months, making it cost and schedule prohibitive. The JV team developed and proposed an integral pre-cast footing system with tubs to form the footing and provide a watertight seal for the placement of footing concrete. This eliminates the costly cofferdam system and accelerates construction.

- Cube Jack Erection: Using cube jacks allows erection of the superstructure independently with no impact on local stakeholders and significantly expedites construction by minimizing erection of the bridge superstructure in pieces.

- Design Efficiencies: The plan would minimize the impact, cost, and time to construct the project by reducing pier size while maintaining the look of the existing bridge. The proposed method uses repetitive details and plate sizes to streamline fabrication and erection, and uses robust 42-inch steel pipe piles to provide high lateral capacities while minimizing the number of piles to be installed.

- Early Delivery Schedule: Elimination of the work trestle and use of cube jacks will enable the team to commit to delivering the project 11 months early, reducing costs for VPRA and minimizing the construction impact to rail service, nearby amenities, and the public.