In The News

An Introduction to Alternative Procurement Delivery

September 12, 2023

By Scott Rhine PE, DBIA, Director of Alternative Delivery at S&B USA Construction

The time has come to change the way public entities replace and expand infrastructure. Traditional methods are becoming less viable as larger projects arise because of aging infrastructure which needs to be repaired or replaced. The infusion of federal dollars due to the Bipartisan Infrastructure Law gives state and local governments the opportunity to rehabilitate or replace deficient infrastructure now, but only if the Commonwealth’s procurement embraces alternative delivery methods such as Design-Build Best Value, CM/GC or CMAR, Progressive Design-Build, and Public-Private Partnerships.

What delivery method has been traditionally used?

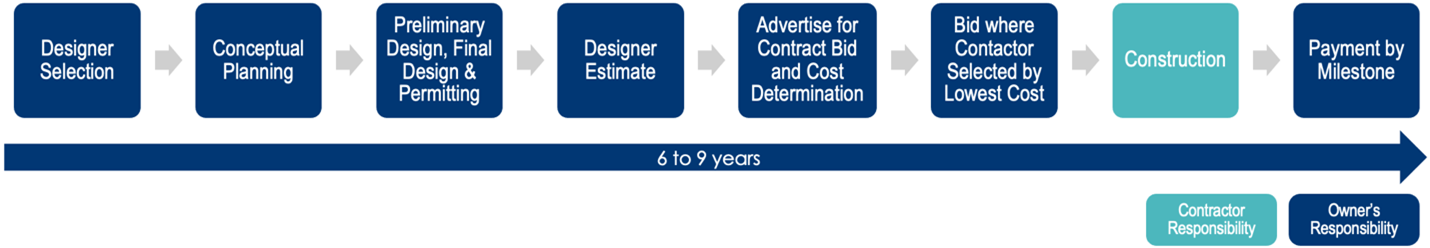

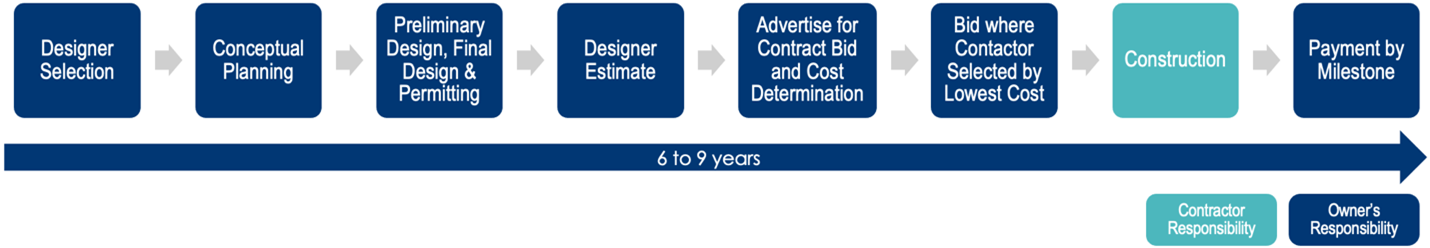

Historically, most construction projects have been delivered through a method called Design-Bid-Build (DBB), which has been colloquially referred to as “rip-and-read.” For these bids, price is the only deciding factor. As long as the bidder meets a few minimum requirements, the company with the lowest price wins the project. Using the DBB process, the owner works with an engineering firm to design the project, and construction companies then bid to build the exact structure the drawings outline. Because of this, DBB prevents the construction companies from being involved in the design process, which negates them from preemptively voicing their constructability concerns, introducing more cost-effective means and methods, and recommending alternative materials with equal or greater value at the same or lower costs.

What is alternative delivery and what are its benefits?

Alternative delivery procurements come in many forms and can optimize project delivery. However, they all have a few commonalities:

1. Faster Delivery: The owner, engineering company and contractor collaborate from the beginning of the procurement process to ensure the constructability of the project design. This partnership improves the project’s schedule and yields better results.

2. Lower Cost: Because of this collaboration, the owner’s cost is reduced as fewer issues arise during construction, and the fast-tracked schedule allows the project to be completed with less labor expenses.

3. Innovation: In the majority of alternative delivery cases, innovative designs that will improve a project’s constructability are discovered. These are called Alternative Technical Concepts (ATCs), or Innovative Technical Concepts (ITCs). During the bid process, contractors are asked to provide ideas that will improve the quality, cost and delivery time of the project. These concepts are then weighed into the decision-making process to determine who wins the work based on the best project value, rather than price alone.

What are the different types of delivery methods and what are the differences between them?

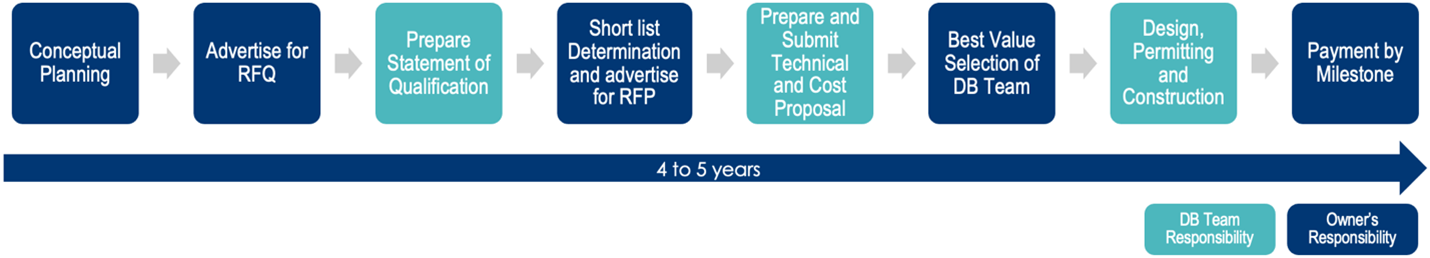

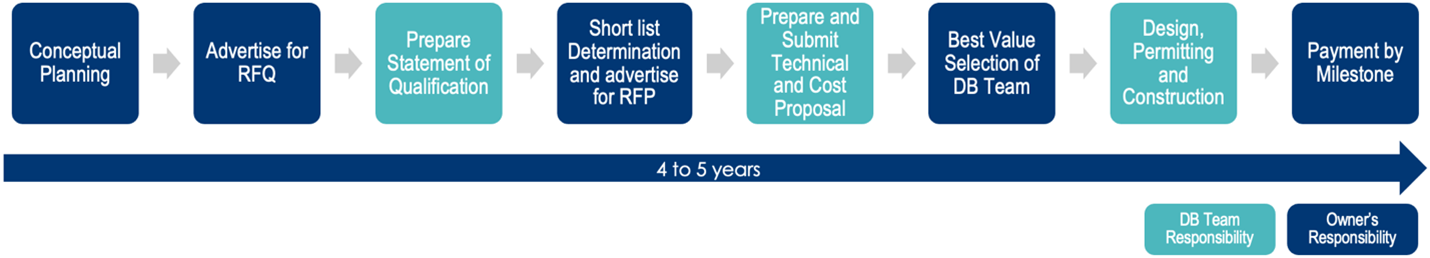

Design-Build Best Value (DBBV), or in most states this is just referred to as Design-Build (DB) In DBBV delivery, the winner is chosen based on both price and technical qualifications. The client determines the weight of each factor, allowing them to customize what best-value means to them. Typically, the construction company and an engineering firm form a team to work together on the pursuit, which ensures the constructability of the design. The selection process is typically separated into two steps, in the first of which a few teams are short-listed based on their submissions in accordance with the owner’s Request for Qualifications (RFQ). This allows the owner to narrow the field to teams they believe will provide the best solutions for the project at hand due to the teams’ expertise (in terms of both personnel and past projects of a similar nature) prior to advancing to the next phase. The second phase is called a Request for Proposal (RFP), where the team explains how their firm would approach the project and provide a price estimation. Proposals are then scored based on how well they fit the owner’s needs, and the best team is selected to complete the design and construction of the project.

The time has come to change the way public entities replace and expand infrastructure. Traditional methods are becoming less viable as larger projects arise because of aging infrastructure which needs to be repaired or replaced. The infusion of federal dollars due to the Bipartisan Infrastructure Law gives state and local governments the opportunity to rehabilitate or replace deficient infrastructure now, but only if the Commonwealth’s procurement embraces alternative delivery methods such as Design-Build Best Value, CM/GC or CMAR, Progressive Design-Build, and Public-Private Partnerships.

What delivery method has been traditionally used?

Historically, most construction projects have been delivered through a method called Design-Bid-Build (DBB), which has been colloquially referred to as “rip-and-read.” For these bids, price is the only deciding factor. As long as the bidder meets a few minimum requirements, the company with the lowest price wins the project. Using the DBB process, the owner works with an engineering firm to design the project, and construction companies then bid to build the exact structure the drawings outline. Because of this, DBB prevents the construction companies from being involved in the design process, which negates them from preemptively voicing their constructability concerns, introducing more cost-effective means and methods, and recommending alternative materials with equal or greater value at the same or lower costs.

What is alternative delivery and what are its benefits?

Alternative delivery procurements come in many forms and can optimize project delivery. However, they all have a few commonalities:

1. Faster Delivery: The owner, engineering company and contractor collaborate from the beginning of the procurement process to ensure the constructability of the project design. This partnership improves the project’s schedule and yields better results.

2. Lower Cost: Because of this collaboration, the owner’s cost is reduced as fewer issues arise during construction, and the fast-tracked schedule allows the project to be completed with less labor expenses.

3. Innovation: In the majority of alternative delivery cases, innovative designs that will improve a project’s constructability are discovered. These are called Alternative Technical Concepts (ATCs), or Innovative Technical Concepts (ITCs). During the bid process, contractors are asked to provide ideas that will improve the quality, cost and delivery time of the project. These concepts are then weighed into the decision-making process to determine who wins the work based on the best project value, rather than price alone.

What are the different types of delivery methods and what are the differences between them?

Design-Build Best Value (DBBV), or in most states this is just referred to as Design-Build (DB) In DBBV delivery, the winner is chosen based on both price and technical qualifications. The client determines the weight of each factor, allowing them to customize what best-value means to them. Typically, the construction company and an engineering firm form a team to work together on the pursuit, which ensures the constructability of the design. The selection process is typically separated into two steps, in the first of which a few teams are short-listed based on their submissions in accordance with the owner’s Request for Qualifications (RFQ). This allows the owner to narrow the field to teams they believe will provide the best solutions for the project at hand due to the teams’ expertise (in terms of both personnel and past projects of a similar nature) prior to advancing to the next phase. The second phase is called a Request for Proposal (RFP), where the team explains how their firm would approach the project and provide a price estimation. Proposals are then scored based on how well they fit the owner’s needs, and the best team is selected to complete the design and construction of the project.

“Design-build, when done right, uses a competitive process focused on qualifications, past performance and technical approaches, with price being less of a factor than in traditional design-bid-build. This creates competition based on the most important factors affecting a project’s success since it increases the likelihood of awarding the project to an exceptional design-builder that produces high-quality work.” Design-Build Institute of America https://dbia.org/blog-mythbusting-design-build-myths-and-facts/

Other alternative delivery processes can also help in situations where the owner needs help defining what they are looking for in a project and how to best approach their needs. In these instances, the owner invites a designer and contractor team to collaborate prior to determining the price.

Construction Manager/General Contractor (CM/GC) or Construction Management at Risk (CMAR)

CM/GC or CMAR differs from DBBV in that there are two contracts. The engineer is not part of the construction team and is instead contracted by the owner directly. However, since the construction team is involved early in the process, the advantages to using Design-Build are similar. The owner, designer and contractor collaborate to set the guaranteed maximum construction price (GMP) at approximately 60% design development. The construction entity chosen is committed to delivering the project at the agreed upon GMP.

Progressive Design-Build (PDB)

PDB utilizes a combination of the procurement elements from CM/GC and DBBV. A Design-Build team consisting of a contractor and designer is selected as a team based on their technical qualifications and a preliminary price estimate. The selected Design-Build team works with the owner to further define their needs through a very transparent process, and they work together to determine the GMP at approximately 60% design development. This adds a level of partnership and results in a well-planned solution and a mutually agreed upon price instead of basing the cost on the RFP preliminary price estimate.

Public-Private Partnership (P3)

P3 is a collaborative model between the owner, typically a government entity, and a private developer (Concessionaire) in which some risk is transferred to the private sector. This model often comes in the form of a Design-Build-Finance-Operate-Maintain (DBFOM) project, where the developer helps the owner obtain the financing for the project, partners with engineers to help create the design, performs the construction of the project, and then operates and maintains the project for a period of time, often 20-30 years or more. Developers can be repaid for their efforts through availability payments over time after the construction is completed, similar to mortgage payments, or through collection of tolls.

P3 projects don’t have to cover all aspects of a DBFOM—they can leave out steps, such as the operations and maintenance of the asset after construction, which would then fall to the project’s owner. This is called DBF.

“P3s offer governments a way to transfer risks to the private sector, help ensure infrastructure projects are built on time and on budget, and better maintain public facilities over many decades, protecting the taxpayer.” Association for the Improvement of American Infrastructure (AIAI). https://aiai-infra.org/resource-center/

Conclusion

There are three influencing components that should be used to determine which type of procurement delivery method an owner should choose: complexity, schedule and cost. Each project has unique characteristics, so owners need to understand which delivery methods are available to choose from to best suit their needs. The more complex a project is, the tighter the schedule, and the overall importance of total project cost (not just construction), will necessitate level and need for constructor involvement as early as possible and this should align with the selected delivery method. Determinants also include the financing abilities of the owner, the timing of owner funding, and what level of innovation the owner is hoping to achieve.

Given Pennsylvania’s infrastructure needs and the availability of federal funding, utilizing alternative delivery procurements more frequently will result in an expedited project delivery schedule and improved public safety.

Construction Manager/General Contractor (CM/GC) or Construction Management at Risk (CMAR)

CM/GC or CMAR differs from DBBV in that there are two contracts. The engineer is not part of the construction team and is instead contracted by the owner directly. However, since the construction team is involved early in the process, the advantages to using Design-Build are similar. The owner, designer and contractor collaborate to set the guaranteed maximum construction price (GMP) at approximately 60% design development. The construction entity chosen is committed to delivering the project at the agreed upon GMP.

Progressive Design-Build (PDB)

PDB utilizes a combination of the procurement elements from CM/GC and DBBV. A Design-Build team consisting of a contractor and designer is selected as a team based on their technical qualifications and a preliminary price estimate. The selected Design-Build team works with the owner to further define their needs through a very transparent process, and they work together to determine the GMP at approximately 60% design development. This adds a level of partnership and results in a well-planned solution and a mutually agreed upon price instead of basing the cost on the RFP preliminary price estimate.

Public-Private Partnership (P3)

P3 is a collaborative model between the owner, typically a government entity, and a private developer (Concessionaire) in which some risk is transferred to the private sector. This model often comes in the form of a Design-Build-Finance-Operate-Maintain (DBFOM) project, where the developer helps the owner obtain the financing for the project, partners with engineers to help create the design, performs the construction of the project, and then operates and maintains the project for a period of time, often 20-30 years or more. Developers can be repaid for their efforts through availability payments over time after the construction is completed, similar to mortgage payments, or through collection of tolls.

P3 projects don’t have to cover all aspects of a DBFOM—they can leave out steps, such as the operations and maintenance of the asset after construction, which would then fall to the project’s owner. This is called DBF.

“P3s offer governments a way to transfer risks to the private sector, help ensure infrastructure projects are built on time and on budget, and better maintain public facilities over many decades, protecting the taxpayer.” Association for the Improvement of American Infrastructure (AIAI). https://aiai-infra.org/resource-center/

Conclusion

There are three influencing components that should be used to determine which type of procurement delivery method an owner should choose: complexity, schedule and cost. Each project has unique characteristics, so owners need to understand which delivery methods are available to choose from to best suit their needs. The more complex a project is, the tighter the schedule, and the overall importance of total project cost (not just construction), will necessitate level and need for constructor involvement as early as possible and this should align with the selected delivery method. Determinants also include the financing abilities of the owner, the timing of owner funding, and what level of innovation the owner is hoping to achieve.

Given Pennsylvania’s infrastructure needs and the availability of federal funding, utilizing alternative delivery procurements more frequently will result in an expedited project delivery schedule and improved public safety.